Blog

Radiation Protection Nanocomposite Material Invention

Research Team Profile

The Radiation Protection Materials Research Group, affiliated with the School of Materials Science and Engineering/State Key Laboratory of Environment-friendly Energy Materials, consists of 8 full-time and 10 part-time researchers (including 4 visiting professors) with multidisciplinary backgrounds in chemistry, materials science, and physics. Currently supervising 30+ graduate students.

Research Focus

- Radiation shielding & decommissioning decontamination

- Hydrogen isotope separation & barrier materials

- Thermal energy storage & transport

- Dielectric energy storage materials

Key Collaborators

- China Academy of Engineering Physics

- Nuclear Power Institute of China

- Academy of Military Sciences Chemical Defense Institute

- China Institute of Atomic Energy

Achievements

- 80+ SCI papers in top journals (Appl. Phys. Lett., J. Membrane Sci., etc.)

- 20+ authorized Chinese patents

-

Recipient of multiple awards including:

- Second Prize, China Petrochemical Science & Technology Award

- Third Prize, Military Science Progress Award

Principal Inventor: Zhang Quanping, Ph.D.

- Education: Ph.D in Materials Processing Engineering, Sichuan University (2014)

-

Research Focus:

- Radiation shielding materials

- Wearable dielectric energy storage systems

- International Experience: Visiting scholar at Institut de chimie de la matière condensée de Bordeaux (2020-2021)

-

Projects Led: 11 research projects including:

- National Natural Science Foundation projects

- National Defense Industrial projects

- Publications: 60+ papers in APL, JMCC, etc.

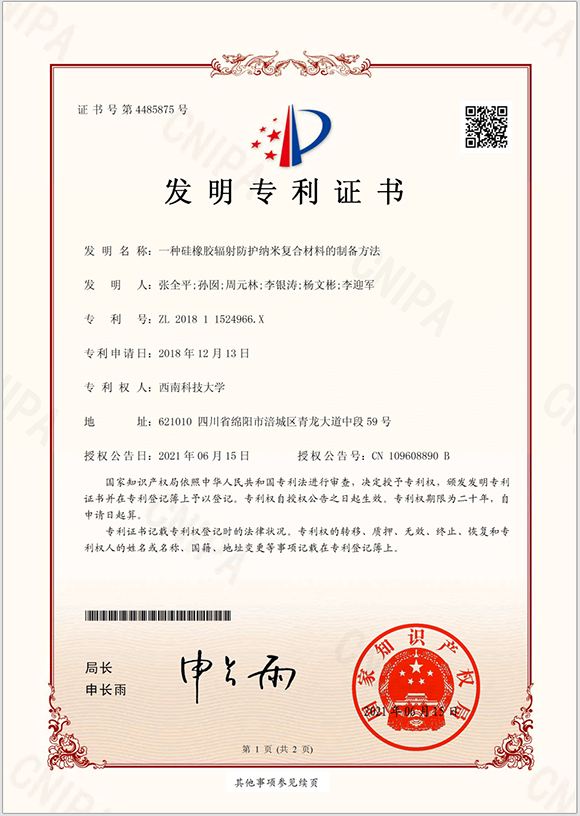

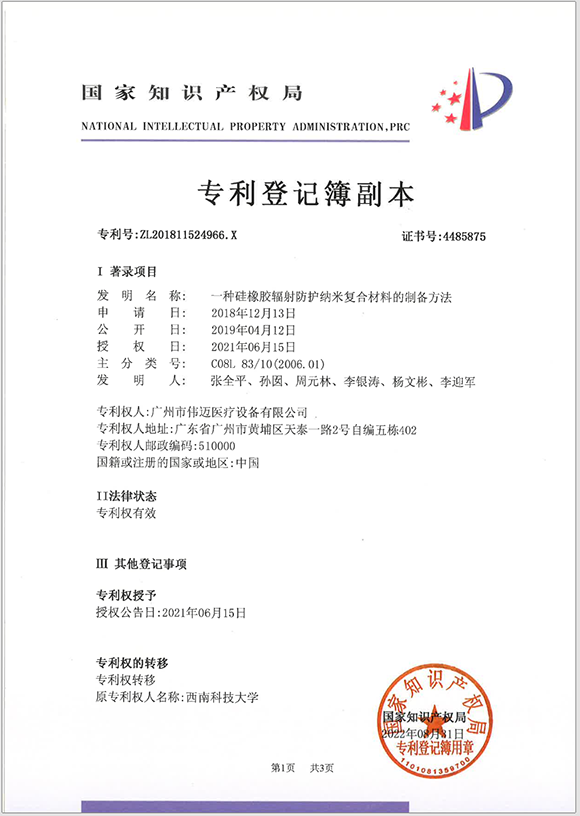

- Patents: 4 authorized national patents

Silicon Rubber Radiation Shielding Nanocomposite

Technical Field

Nuclear radiation protection technology: A preparation method for flexible radiation shielding nanocomposites combining silicone rubber with functional nanostructures.

Technical Challenges

- Density mismatch causing filler sedimentation (>90% density variance)

- Poor interface compatibility in high-filler systems (<50% bonding efficiency)

Innovative Solution

- Surface hydroxylation & silane coupling agent modification

- High-speed mixing (2000-3000 rpm) & controlled curing process

Technical Parameters

| Property | Value |

|---|---|

| Filler Loading Capacity | 0-90 wt% |

| Neutron Shielding (0.025eV) | 35% attenuation |

| Gamma Shielding (105keV) | 83% attenuation |

| Tensile Strength | ≥5MPa |

Application Fields

- Nuclear facility maintenance

- Radiation emergency response

- Medical radiation protection

For technical specifications: Contact us

CATEGORIES

LATEST BLOG

CONTACT US

Contact: Sarah Huang

Phone: +8613450296537

Tel: +86 20 82171811

Email: 4000131811@viewmed.co

Add: 3F, Building A1, Xicheng Ave. M. Guangzhou, China

+44 7962 618630

+44 7962 618630  4000131811@viewmed.co

4000131811@viewmed.co